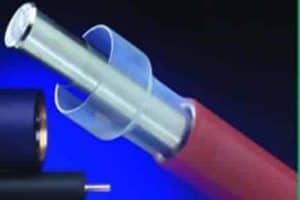

1 1/2 Heat Shrink FEP Roll Cover • 1.5RC

| Item | Heat Shrink Specification |

|---|---|

| Part | 1 1/2 FEP Roll Cover |

| Material | FEP |

| Mil - Spec | ASTM D2902 TYPE II |

| Ratio | 1.25:1 |

| Color | Clear |

| Nominal Size | 1 1/2 |

| Expanded ID | 1.700 |

| Recovered ID | 1.300 |

| Wall | .020 +/- .003 |

| Lengths | up to 10 ft |

| Max Service Temp | 400 ° F |

| Bondable | Upon Request |

Heat Shrink FEP Roll Covers are produced in straight length to avoid and kinks or creases. Manufactured and stocked in lengths up to 10 ft. Longer lengths also available upon special quotation. FEP Roll covers also come with the option of being supplied etched with adhesive for bonding.

Heat Shrink FEP Roll Covers are easier to shrink than PTFE and can withstand temperatures as high as 400°F (204°C). Shrinkable FEP Tubing is supplied in an expanded state to allow easy coverage over instruments such as Thermocouples, Probes, Thermometers, Lighting Fixtures and other delicate electrical instruments where protection is needed. FEP provides a tight seal around components, protecting them from harsh chemical environments. As a protective sleeve, FEP helps eliminates dirt and contamination build up on components.

Tef Cap Industries manufactures both Mil-Spec and Custom Heat Shrink Tubing in FDA and USP Class VI Compliant resins such as FEP, PFA and PTFE.

Heat Shrink FEP Roll Covers Specifications:

- Tubing produced from 100 % Virgin FEP (Fluorinated Ethylene Propylene) resins.

- Supplied in lengths from 2 ft to 10 ft.

- Shrink Temperature: Below 1.00” Diameter – 410°F/210°C – Over 1.00” Diameter – 430°F/221°C.

- Color: Clear / Translucent, Custom Colors are available.

- FEP 1:3 – AMS-DTL-23053/11 Class 1

- FEP 1:6 – AMS-DTL-23053/11 Class 2

- FDA Compliant

- USP Class VI Compliant

- Reach & RoHs Compliant

- VW1, UL-83

Heat Shrink FEP Roll Covers Applications:

- Protective Covering For Components

- Electrical Insulation

- Laminating / Conveyor Rollers

- T5,T8,T12 Light Covering

- Dryer Cans

- Battery Packs

- Print Rollers

Heat Shrink FEP Roll Covers Characteristics:

- Biocompatible, FEP is certified USP Class VI

- Maximum heat resistance up to 400°F (204°C)

- Chemically inert to nearly all industrial chemicals and solvents

- Eliminates dirt and contamination build up on components

- Lower gas and vapor permeability than PTFE

- Low absorption of solvents (< 1%)

- Gamma, ETO, e-beam and autoclave sterilizable

- Excellent transmission of ultraviolet rays

- Self-extinguishing

- Non-wetting