Heat Shrink Dual Wall PTFE/FEP Tubing

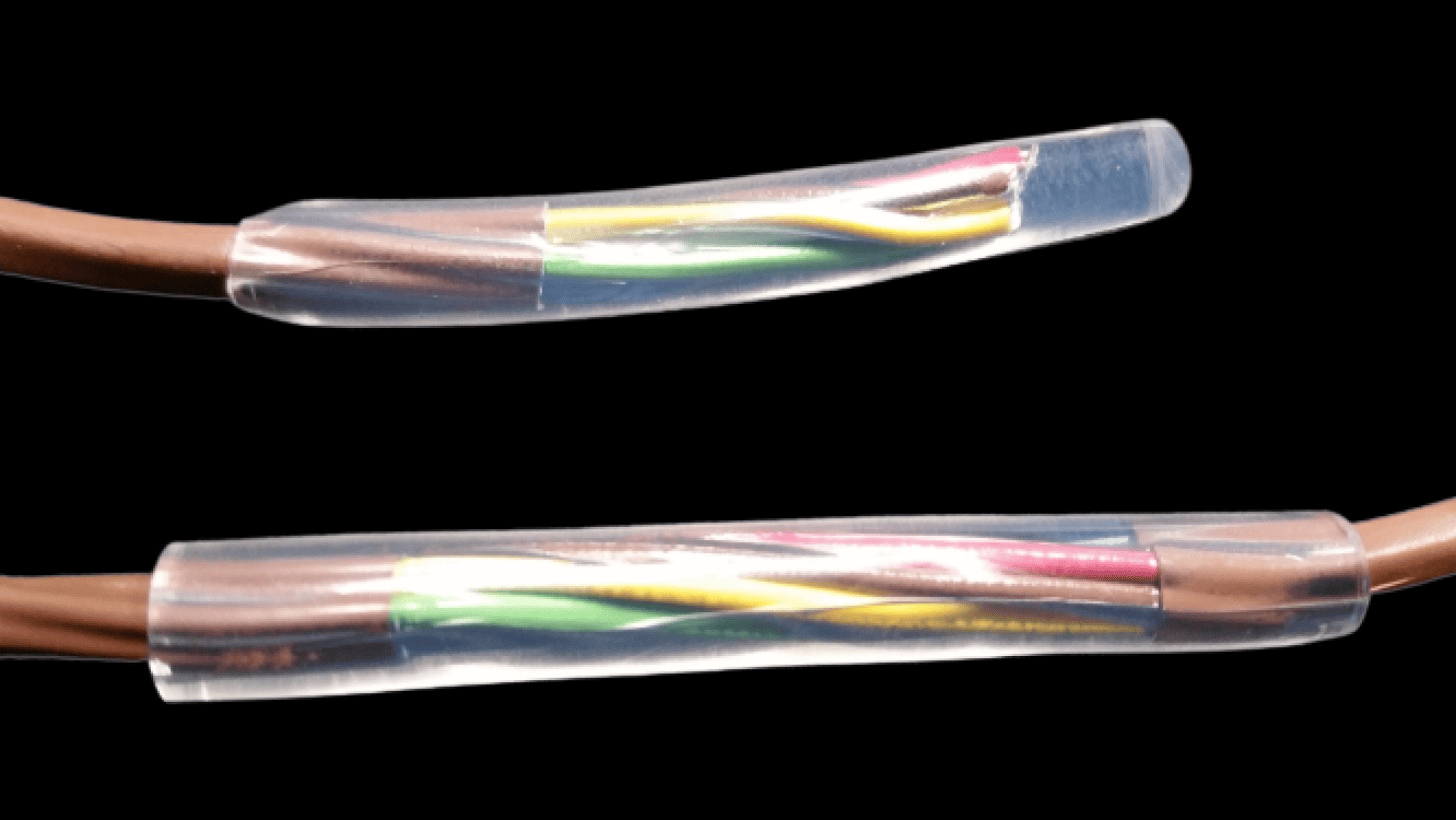

Dual Wall PTFE FEP or Dual Shrink is designed to provide a tight, moisture-proof bond over wires, cables, connectors, splices, terminals. Dual Wall material can also be used as an end cap for wires. Tef Cap’s Dual Wall PTFE / FEP has a continuous operating temperature up to 450° F ( 232° C ) and can see temperatures as low as -328° F ( -200° C ).

Old specifications such as PennTube WTF can be crossed referenced to newer part numbers such as TSSS : Standard Wall and TSSL : Light Wall.

Dual Shrink PTFE/FEP Light Wall

| Dual Wall PTFE/FEP | Min. Supplied ID | Recovered ID | Wall After Shrinking |

|---|---|---|---|

| TSSL065 | .065 | .000 | |

| TSSL115 | .115 | .045 | .015 |

| TSSL130 | .130 | .060 | .015 |

| TSSL190 | .190 | .070 | .015 |

| TSSL240 | .240 | .150 | .020 |

| TSSL350 | .350 | .210 | .025 |

| TSSL480 | .480 | .315 | .032 |

Dual Shrink PTFE/FEP Standard Wall

| Dual Wall PTFE/FEP | Min. Supplied ID | Recovered ID | Wall After Shrinking |

|---|---|---|---|

| TSSS036 | .036 | .000 | |

| TSSS060 | .060 | .000 | |

| TSSS130 | .130 | .000 | |

| TSSS160 | .160 | .000 | |

| TSSS190 | .190 | .062 | .035 |

| TSSS250 | .250 | .125 | .035 |

| TSSS350 | .350 | .190 | .035 |

| TSSS450 | .450 | .312 | .055 |

PTFE/FEP Encapsulation

When the most robust protection from environmental exposure is required, employ dual wall heat shrink to secure sensitive components and electrical junctions. Heat shrinkable tubing provides a tight, moisture-resistant bond over wires, cables, connectors, sensors, terminals and splices to protect them from extreme environmental conditions, including heat, corrosion, shock and moisture.

Tef Cap manufactures high-performance heat shrinkable tubing using various fluoropolymer resins. Our Dual-Wall Heat Shrink tubing is designed with the end user in mind, as we ensure secure and consistent tolerances on shrinkage to facilitate automated assembly processes.

Dual-Wall Heat Shrink from tef Cap tubing has an outer layer of PTFE and an inner layer of FEP that offers a maximum longitudinal variation of +0%/-15% after application. When heated, the inner FEP layer melts and encapsulates the junction to eliminate voids and air channels to withstand extreme environmental conditions. The high service temperature outer PTFE layer compresses the molten FEP, creating a liquid and vapor-tight seal.

Available in a variety of sizes, dimensions, and shrink ratios, our high-performance fluoropolymer heat shrinkable tubing can be customized to meet your unique needs to ensure maximum protection, reliability and performance.

Light : TSSL065, TSSL115, TSSL130, TSSL190, TSSL240, TSSL350, TSSL480, TSSL700, TSSL1000

Standard : TSSS036, TSS060, TSSS130, TSSS160, TSSS190, TSSS250, TSSS350, TSSS450, TSSS700, TSSS950

Protect High Temperature Components from External Conditions

As a critical partner of heat-shrinkable, temperature-resistant shrink PTFE tubing and transparent FEP to numerous companies in the electrical, semiconductor, aerospace, medical, and chemical processing industries, Tef Cap Industries is the go-to resource for companies wanting to protect their electronic devices and sensitive finished goods. Our polytetrafluoroethylene (PTFE/FEP), commonly called Dual Shrink, is a dual wall heat shrink tubing solution that is temperature-resistant and has excellent low coefficient of friction properties alongside superior chemical resistance.

With over 50 years of hands-on experience providing time-critical deliveries of transparent FEP, dual wall PTFE/FEP tubing, and other heat-resistant shrink tubing products, Tef Cap Industries ensures your components are always protected from the elements.

The ideal industrial wall Teflon tubing solution, PTFE, provides an impenetrable barrier that helps to protect electrical components, subcomponents, integrated electronic assemblies, wiring, sensors, medical devices, and cables while ensuring a tight, snug fit.

Once the heat is applied to our PTFE dual wall shrink tubing solution, it immediately seals your components, providing an effective electrical insulation barrier that protects your electrical components against the elements.

What are the Best Scenarios for Utilizing Dual Wall Tubing?

- Harsh chemical environments: No matter what your operating conditions are or where your parts are located, our dual wall PTFE heat shrink tubing will protect your components from the harshest of chemicals.

- High-temperature and abrasion resistance: Relied on for its incredible chemical resistance and abrasion resistance properties, our PTFE shrink tubing is an extremely flexible, durable, fluorinated polymer that can withstand temperatures between 330°F to 500°F.

- Electrical insulation and protection: With its air-tight barrier, our PTFE dual wall heat shrink tubing not only protects your components from damage but also provides effective electrical insulation.

- Medical and food contact applications: From protecting sensitive medical devices to being used extensively in food processing, our PTFE heat shrink tubing is the ultimate solution.

- Fluid and gas transfer with specific requirements: As the ideal fluid and gas management solution, our PTFE heat shrink tubing provides superior chemical inertness, ensuring an even flow of fluids and gases without contamination.

- Applications requiring a combination of properties: Whether it’s protecting electronics, integrated systems, or need to ensure uninterrupted fluid transfer, our PTFE heat shrink tubing solutions can accommodate an extensive rate of different operating parameters and applications.

- Cost optimization: From minimizing maintenance and repair costs to reducing the high costs of damaged or defective electronic products, the dual wall FEP tubing provides significant cost-per-use savings that protect your bottom line.

If you have questions about our transparent FEP or PTFE dual wall tubing products and want to better understand how both can protect your components while ensuring optimal fluid flow, contact us now.