PTFE Spiral Wrap • Spiral Cut Tubing

PTFE Spiral Wrap is chemically inert, non-flammable and not affected by corrosive solvents, harsh cleaners, or acids.

PTFE Spiral Wrap is engineered from Standard Industrial Wall PTFE Tubing.

PTFE Spiral Wrap

| Size OD | Size ID | Wall | Bundle Dia. | Pitch |

|---|---|---|---|---|

| 1/8 | 1/16 | .030 | 1/2 | .218 |

| 3/16 | 1/8 | .030 | 1 | .312 |

| 1/4 | 3/16 | .030 | 2 | .375 |

| 5/16 | 1/4 | .030 | 2 1/2 | .375 |

| 3/8 | 5/16 | .030 | 3 | .437 |

| 1/2 | 7/16 | .030 | 4 | .562 |

| 5/8 | 9/16 | .030 | 5 | .625 |

| 3/4 | 11/16 | .032 | 6 | .875 |

| 1 | 15/16 | .040 | 8 | 1 |

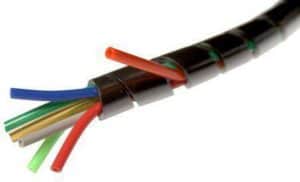

Durable PTFE Spiral Wrap Tubing In Different Sizes And Colors

Spiral Wrap is also available in Nylon and colors for easy identification.

Applicable Specifications: MIL-T-47287, ASTM D 3295.

Operating Temperature: up to 500 F.

Flammability: Self extinguishing

RoHS Compliant

Easy to Unwrap and Check for Issues

At Tef Cap Industries, we make protecting and inspecting wiring simple and streamlined. From traditional PTFE spiral cut tubing to heat shrink dual wall PTFE tubing, our solutions are easy to unwrap and check for issues. When protection from environmental exposure is necessary, Tef Cap Industries PTFE and FEP tubing provide moisture-resistant, tight bonds. Our tubing solutions are suitable for sensors, connectors, wires, cables, and even entire terminals, which protect not only from moisture but also from shock, corrosion, and heat.

Additionally, Tef Cap Industry provides tubing solutions in a variety of shrink ratios, sizes, dimensions, and colors to match your company’s needs, preferences, and demands. We will work with you to ensure your PTFE tubing or FEP solutions are ideal to protect, organize, manage, wrap, and insulate your cables, hoses, and entire systems.

If you are interested in shrinkable PTFE designed in areas of high temperatures, consider dual wall PTFE FEP heat shrinkable tubing or custom spiral cut tubing to suit your project’s specifications. In addition to being easy to unwrap and check for issues, dual wall PTFE/FEP or Dual Shrink can also be useful as an end cap or wire wrap.

The Perfect Solution for Unruly Wires

With PTFE spiral cut tubing, bundling unruly wires and entire systems has never been easier. Tef Cap Industries specializes in spiral-cut tubing and wrap solutions to ensure your system remains functional and always optimized. Some of the most notable benefits of PTFE spiral-cut tubing include the following:

- Protection from long-term wear and tear

- Reduced vibrational output with a tightly sealed wrap

- Reusable tubing

For those new to PTFE spiral cut or custom-cut tubing, a few notable advantages include:

- Versatility: PTFE tubing solutions are extremely flexible, with a range of size, color, thickness, and dimension properties for any project, big or small. PTFE is extremely versatile due to its various applications. From carrying alcohols and chemicals to liquids, acids, and gasses, it provides proper electrical insulation and sleeve wrap solutions.

- Lightweight: For those interested in a more lightweight solution, PTFE may be ideal for your existing or next project. While alternative materials, such as outdated plastics and metals, are heavy, PTFE solutions are suitable for heavy-duty operations without excessive weight.

- Strength: PTFE tubing is also a great choice for those seeking low-density, robust, strength results. Our PTFE tubing solutions are made from compounds that can withstand stress, damage, and cracking impacts–preventing your systems from becoming worn down or fatigued too fast. PTFE tubing is ductile, ensuring the material can flex and expand without cracking or breaking down, even when extremely strained or stressed.

How Does Spiral Cut PTFE Compare to Other Types of Spiral Cut Tubing

Spiral-cut PTFE tubing is unique because of its superior performance in harsh applications. It has special benefits over other materials, and it is the best option for industries that need durability, flexibility, and resistance to harsh environments.

- Better Temperature Resistance – PTFE is resistant to extreme temperatures, ranging from cryogenic temperatures to more than 500°F, without losing its properties.

- Resists Most Chemicals – It is highly resistant to acids, bases, solvents, and other corrosive chemicals, assuring long life in harsh environments.

- Lowest Friction Percentile – PTFE has a very low coefficient of friction, reducing wear and increasing performance in dynamic use.

- Excellent Electrical Insulation – With high dielectric strength, PTFE provides reliable insulation for sensitive electronic and electrical use.

- Non-Flammable – It is extremely resistant to ignition and will not carry combustion making it well-suited to safety-critical applications.

- Biocompatible – PTFE is biologically inert and will not leach toxins. It can be utilized in medical, pharmaceutical, and food-grade applications.

- Bends and Conforms Readily – Its malleable nature makes enveloping cables and components without kinking or cracking simple.

- Extremely Abrasion-Resistant – PTFE withstands mechanical stress, wear, and weathering, ensuring long life in abusive conditions.

To learn more about shrinking instructions regarding PTFE/FEP encapsulation or PTFE spiral cut tubing, contact us online or call 610-692-2576 today.