You might not always notice it, but PTFE is everywhere in daily life. First discovered in 1938, PTFE—commonly known as Teflon—was soon used to coat valves and seals in manufacturing and was even utilized in the Manhattan Project in pipes holding uranium hexafluoride in the enrichment plant in Oak Ridge, Tennessee. Not long thereafter, it was coating cooking pots and pans under the name of Teflon. These days PTFE can be found throughout the automotive and aerospace industries, as well as computers and various consumer products, but what is it that makes this material so remarkable? Here are some of the properties and benefits that explain why PTFE has made such an impact on our modern world.

PTFE’s Unique Properties

PTFE has several properties that has made it suitable for a variety of uses. Some of the most beneficial are its:

- Effectiveness across a broad temperature range

- Low coefficient of friction

- High resistance to most chemicals

- High electrical resistance and dialectical strength

- Nontoxicity

If you’re looking for a substance that’s tough, chemical and water resistant, and affordable, it’s hard to imagine anything more suitable than PTFE.

Applications in the Food and Beverage Industry

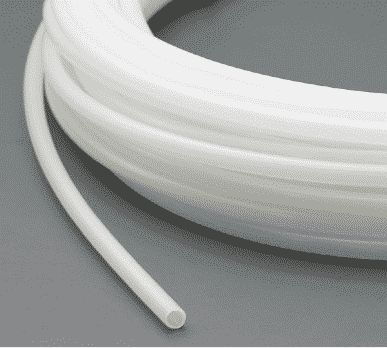

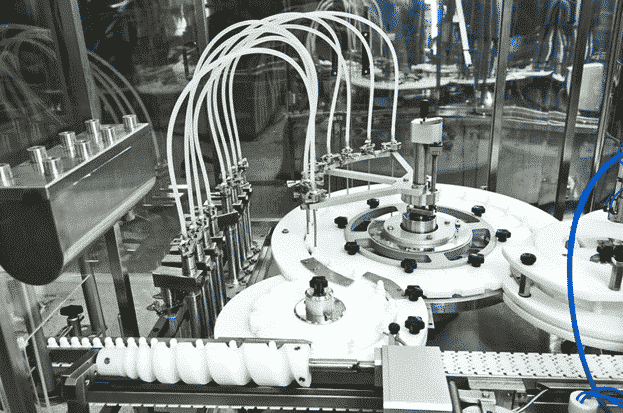

One of PTFE’s most famous properties is its nonstick nature. Blessed with the third-lowest coefficient of friction of all materials, its use in nonstick cookware is well known. Also, the fact that it can easily be formed into tubing makes it particularly useful in the food and beverage industry. PTFE tubing manufacturers make tubes that move liquids in bars, restaurants, and food production that are flexible; nontoxic; and impermeable to food, water, oil and practically all kinds of chemicals. This allows for greater efficiency with zero contamination, while making it virtually impossible for food and bacteria to build up within the hoses.

Aerospace and Computers

About half of all production of PTFE goes into the insulation of wiring in aerospace and computers. Its resistance to heat and its excellent dielectric properties makes it ideal as an insulator in connector assemblies and circuit boards. Furthermore, the fact that it maintains its structural integrity at high temperature (approximately 500° F) and is also chemical resistant makes it ideally suited for use as a hose in aerospace and automotive applications where hazardous chemicals need to be moved while under intense heat.

Health Care Applications

Hospitals and clinics are particularly vulnerable to the spread of infections. That’s why it’s paramount that any device that interacts with bodily fluids aid in keeping the patient and the surrounding area free of bacteria. With its nonstick nature and chemical resistance, PTFE is commonly used as a catheter so that no bacteria has the chance to flourish. It can also be present as a coating on medical instruments and devices, drains, filters, and for the conveyance of gas and liquid substances. PTFE has even been used to create artificial blood vessels and substitutes for bone tissue, tendons, and soft tissues.

You might not need PTFE for a medical procedure, but if want to take advantage of everything PTFE tubing has to offer, you can rely on PTFE tubing supplier Tef-Cap Industries, Inc. For any questions, call us at (610) 692-2576 today.