How Much Heat is Needed for Heat Shrink Tubing? A Quick Guide

If you’ve ever worked with heat shrink tubing, you may have wondered what temperature the tubing needs to see in order to bond to the subsurface materials. The correct amount of heat is needed for proper shrinkage, insulation, and protection. Regardless of...

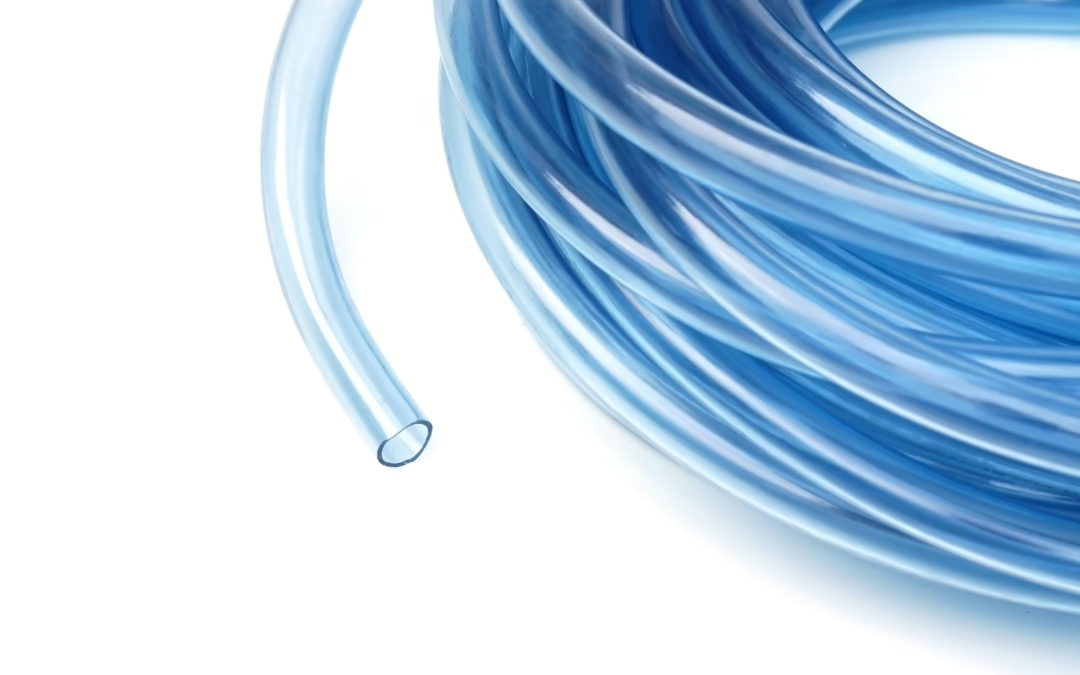

What is PTFE Tubing?

PTFE tubing is an incredibly versatile material that has a wide range of applications across many industries. You might have seen it used without even realizing it—inside your car engine, in laboratories, or as part of critical systems in industries like medical,...

What are the Different Forms of PTFE That Are Used?

Explore the various forms of PTFE, from tubing to spiral wraps, designed for industries like aerospace, automotive, medical, and electronics. Tef Cap provides durable, temperature-resistant, and chemically resistant PTFE solutions tailored to your specific needs.

How Engineers Can Optimize System Performance with Extruded PTFE Tubing

Since the 1930s, PTFE tubing, More commonly referred to as Teflon, has become a go-to game changer for many important industries. It’s probably most famous for providing our kitchen pots and pans with the famous non-stick surface. We take for granted this...

Celebrating 80 Years w/ John Walls

Happy 80'th Birthday to the man who help start it all.....John F. Walls has over 50 years in the Fluoropolymer Industry and still teaching us things everyday. Clifton Plastics , Aston Technical Sales, Dixon, Penn Tube Plastics, Texloc Ltd, Tef Cap Industries and...