Custom Extrusions

Custom Extruded Fluoropolymers

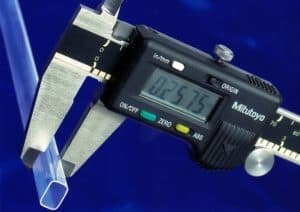

Not all projects are designed the same and not all machines use the same size tube. This is why Tef Cap has made it easy for you to get a custom Fluoropolymer Tube in a size that works for you. Low minimum orders and runs allow you to see, feel and test the products without having to sacrifice.

With the ability to hold tight tolerances in both the extrusion and cutting Tef Cap can provide customers the parts and quality that they deserve. Extruded PTFE, FEP and PFA Tubing can be cut in-line so that the tubing is not bent or curved as if it were cut from a coil and taken a set. Custom colors can also be done for line identification, product concealment or even designed to match your company colors.

With over 50 years of Fluoropolymer experience that stretch back to the emergence of resins such as PTFE, FEP and PFA founder John F. Walls has pushed his employees and propelled his company to become a top competitor in the Fluoroplastic field. From simple extrusions to custom heat shrinkable FEP & PTFE Tef Cap Industries prides itself on not only being a global tubing supplier but also a one stop shop for all your Fluoropolymer secondary processes.

Helping customers

- Shorten down times on costly machines

- Eliminate waste

- Lower material and production costs

- Improve efficiency

Most important

- Improve your bottom line

What are Fluoropolymers?

Tef Cap Industries is an established PFA tubing manufacturing partner to numerous companies requiring chemical-resistant, static dissipative, and temperature-resistant, nonstick custom fluoropolymer extruded tubing for various fluid management processes. For over 50 years, we’ve raised the bar on service and operational excellence by ensuring time-critical deliveries of custom fluoropolymer tubing to high-demand industries requiring uninterrupted liquid flow to integrated assemblies, machinery, and equipment.

Used extensively in automotive engines, aerospace engines, gearboxes, numerous electronics, defense, medical devices, and agricultural equipment as a means of electrical insulation, our Polytetrafluoroethylene (PTFE) extruded tubing is a flexible solution with made-to-fit properties for the tightest areas.

PTFE is a fluoropolymer, a type of resin or plastic where carbon atoms are bonded with fluorine atoms, creating a polymer with incredible chemical and temperature resistance. As a custom PTFE tubing manufacturing company, our PTFE provides a protective barrier against acids, abrasive liquids, chemicals, and solvents.

Custom Tubing Solutions for Any Industry

Our PTFE fluoropolymer extruded tubing is the go-to solution for companies wanting high flow rates without fluid adhesion and resistance. A highly flexible tubing solution, our fluoropolymer extruded PTFE can be bent or adjusted to any tight-fitting application without sacrificing liquid flow and without encountering fluid resistance.

With superior chemical resistance properties and a low friction coefficient, our PTFE is a fluoropolymer tubing solution that can withstand extreme temperature ranges without material degradation. The result is a non-stick tubing solution that provides a smooth and uninterrupted transfer of fluids.

Why is Fluoropolymer an Industry Standard Material?

- Extreme chemical resistance: Its excellent chemical resistance properties mean our fluoropolymer extruded PTFE tubing protects fluid from contamination from the most corrosive of chemicals and solvents.

- High-temperature stability: As a fluoropolymer capable of withstanding 330°F to 500°F, our custom PTFE tubing can withstand the harshest environments.

- Low coefficient of friction: Our custom PTFE tubing has excellent low coefficient of friction properties, which means a high flow rate with minimal fluid friction.

- Excellent electrical insulation: As a polymer with low electrical conductivity properties – in addition to its ability to withstand temperatures that other polymers can’t without degrading – our PTFE tubing possesses excellent dielectric strength properties, which provide superior electrical insulation.

- Weather resistance: With its low surface properties and excellent temperature stability, our PTFE tubing provides the perfect water-repelling and weather-resistant tubing solution.

- Biocompatibility: Our custom PTFE tubing is exceptionally biocompatible, which ensures its safety as a critical material for medical devices.

- Versatility: An exceptionally flexible, versatile tubing solution with incredible non-stick characteristics, our custom fluoropolymer tubing can be used in various applications and can be bent, angled, and used in numerous tight-fitting applications.

If you are interested in the PTFE custom tubing provided by Tef Cap Industries but have questions about different properties, contact us now.