Etching Fluoropolymer Tubing

Etching Fluoropolymers is the only true way to help improve the bond between Teflon Tubing and its mating parts without sacrificing the mechanical properties of the tubing. Etching tubing can be a very unpleasant experience due to the chemicals that are involved. While most etching compounds are safe to use they still need to be disposed of properly and can leave a lasting smell.

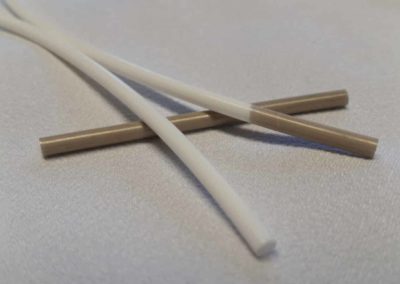

Sodium-etching of Fluoropolymers such as PTFE and FEP is a well established technology and is often used on Heat Shrinkable Roll covers that have high NIP pressures. While Etching of Fluoropolymers does turn the surface of the material a light brown and makes for a clear visible sign that the process has been completed, darker brown spots do not indicate a better etched area.

With over 50 years of Fluoropolymer experience that stretch back to the emergence of resins such as PTFE, FEP and PFA founder John F. Walls has pushed his employees and propelled his company to become a top competitor in the Fluoroplastic field. From simple extrusions to custom heat shrinkable FEP & PTFE Tef Cap Industries prides itself on not only being a global tubing supplier but also a one stop shop for all your Fluoropolymer secondary processes.

Helping customers

- Shorten down times on costly machines

- Eliminate waste

- Lower material and production costs

- Improve efficiency

Most importantly

- Improve Your Bottom Line