An important development in fluid handling is PFA tubing. For industries needing dependable, long-lasting, and chemically resistant tubing, this high-performance Fluoropolymer is the material of choice. What characteristics make PFA tubing so popular for demanding applications? Perfluoroalkoxy alkane, or PFA, is a particular kind of fluoropolymer tubing that has strong thermal stability and chemical resistance. It works well in challenging conditions, such as exposure to extremely high or low temperatures, where other materials might not last. Because of its durability, PFA tubing can be used in the pharmaceutical, semiconductor, and chemical processing industries.

PFA tubing is extremely versatile in addition to being durable. Its non-stick, smooth surface makes cleaning easier and helps avoid buildup, both of which are essential for preserving high purity. This trait is especially helpful in sectors that place a high value on purity, like food processing and the production of medical devices, including those that involve food contact.

What Sets PFA Tubing Apart?

PFA tubing has several qualities that set it apart from other materials. These characteristics contribute to its outstanding performance in a variety of settings. Selecting the best tubing for a particular application is made simpler by being aware of these features. One of the best qualities of PFA tubing is its resistance to chemicals. It can tolerate a wide range of hostile substances without degrading, including most acids, bases, and solvents. This suggests that these abrasive materials can be moved without damaging the tubing or contaminating the liquid.

This level of stillness is crucial for applications where even a small amount of contamination can have adverse effects. Examples include handling high-purity chemicals in laboratories and fabricating semiconductors, both of which depend on ultra-pure chemicals. PFA tubing helps maintain process integrity and product purity, especially when high purity PFA resins are used.

Wide Temperature Range Tolerance

PFA tubing performs exceptionally well across a wide temperature range. It maintains its structural integrity and mechanical properties at temperatures between about -200°C (-328°F) and 260°C (500°F). It can be used in cryogenic and high-temperature processes due to its broad range of operation. This thermal durability is crucial for many industrial processes. PFA tubing is reliable in handling hot, aggressive chemicals and can withstand sterilization procedures like autoclaving without undergoing physical changes. The fact that it can tolerate extremely high or low temperatures adds to its dependability and safety.

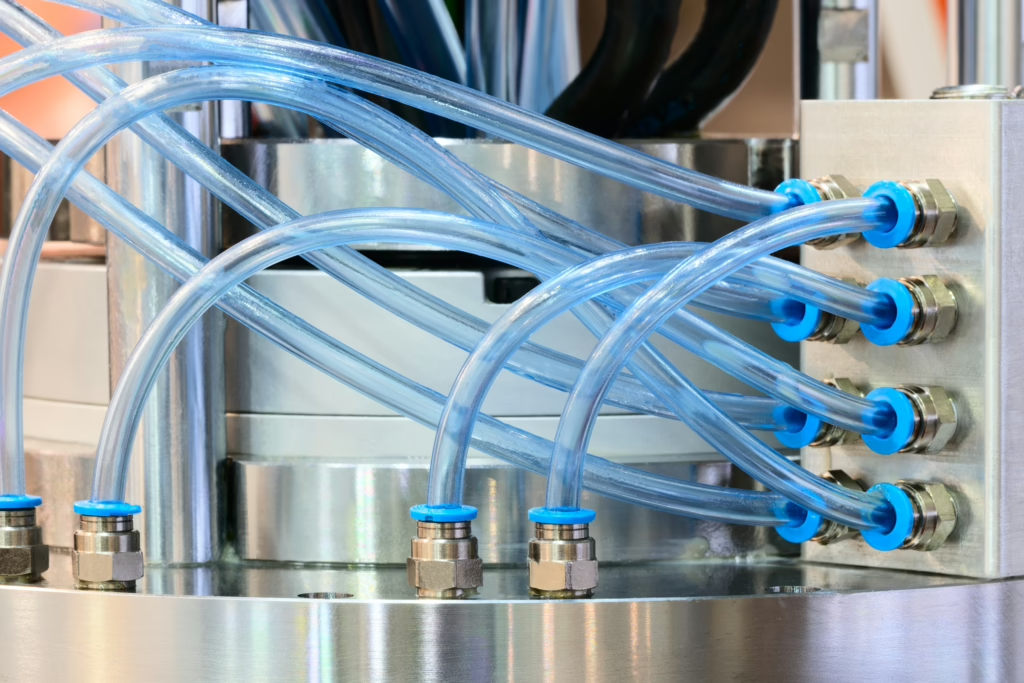

Flexibility and Mechanical Durability

Despite its durability, PFA tubing offers a fair amount of flexibility. This makes installation easier, especially in complex configurations, and reduces the chance of kinking or collapsing while in use. Its adaptability also aids in absorbing system vibrations, potentially extending the lifespan of linked components. PFA tubing is well known for its long lifespan and resilience. It exhibits exceptional resistance to fatigue, environmental stress cracking, and cracking even under challenging operating conditions. Because of its inherent toughness, the equipment has good tensile strength over its lifetime, which reduces maintenance, downtime, and replacement costs overall.

High Purity and Low Extractables

For situations where the highest level of sanitation is required, such as in a setting where hygiene is a concern, High Purity PFA tubing is an excellent choice. Since impurities are reduced during the production process, these grades have extremely low amounts of extractables. This suggests that impurities from the material itself won’t seep into the fluid the tube is transporting. Additionally, PFA has a very low moisture absorption rate. In circumstances where moisture might interfere with processes or the quality of the finished product, this feature is crucial. Because it is non-porous, it is suitable for systems with high purity.

Superior Electrical Insulation Properties

Additionally, PFA tubing has strong electrical insulation qualities. It is a good material for applications requiring electrical isolation because of its high dielectric strength. In the production of electronics or in machinery where tubing may come into contact with electrical components, this can be especially crucial. Its electrical characteristics, along with its resistance to chemicals and temperatures, make it valuable in specific applications, such as sophisticated scientific equipment or data center cooling systems. The substance aids in preventing interference and electrical discharge.

Key Applications of PFA Tubing

PFA tubing’s benefits make it perfect for a variety of uses across various industries. Its reliability under trying conditions is a key factor in its selection. Let’s look at a few significant industries that use PFA tubing extensively.

Semiconductor Manufacturing

In the semiconductor industry, extremely stringent purity standards are enforced. Even the smallest impurities can cause integrated circuits to malfunction. PFA tubing, especially high purity PFA, offer the chemical resistance and exceptionally smooth, non-leaching interior surfaces needed for the transportation of ultra-pure water, solvents, and specialty gases used in wafer fabrication and chip manufacturing in a clean room setting.

Chemical Processing

Chemical facilities often handle highly reactive or corrosive substances that can harm a variety of common tubing materials. PFA tubing is ideal for safely and reliably handling these harsh chemicals due to its broad range of chemical resistance. Reactor parts, chemical transfer lines, sampling systems, and systems requiring double containment for enhanced safety all use it.

Pharmaceutical and Biotechnology Industries

In the pharmaceutical and biotech sectors, upholding product sterility and purity is essential. PFA tubing often fulfills FDA regulations and other regulatory requirements for extractables and biocompatibility. Because of its non-reactive nature and resistance to common sterilizing methods like autoclaving, it is a popular choice for drug manufacturing, diagnostic equipment, and bioprocessing lines.

Food and Beverage Industry

Materials that are easy to clean and sanitize and safe for food contact are essential for the food and beverage industry. PFA tubing successfully satisfies these requirements; numerous grades are FDA-compliant for use in food contact. In the food processing and beverage industries, its non-stick surface helps to maintain high hygiene standards by preventing the accumulation of food particles and microbial growth. It frequently outperforms stainless steel in this area.

Analytical and Laboratory Instrumentation

PFA tubing is frequently found in analytical devices like spectrometers, titration apparatus, and chromatographs (HPLC, GC). Because of its chemical inertness, skewed analytical results are prevented because the tubing won’t interact with samples or standards. For applications where even minute amounts of contamination can jeopardize measurement accuracy and dependability, this feature is needed.

Environmental Monitoring and Sampling

PFA tubing is commonly used in environmental testing to collect samples of soil, water, and air where sample integrity is crucial. Analytes are less likely to adhere to the tubing walls due to its poor adsorption properties, particularly at low concentrations. By doing this, the gathered samples are guaranteed to faithfully reflect the original environment.

Automotive and Aerospace

Fluids are frequently exposed to harsh chemicals and extremely high temperatures in the automotive and aerospace industries. Fuel lines, hydraulic systems, and other fluid transport applications where dependability and high performance are essential can all benefit from the use of PFA tubing. A further benefit is that it is lighter than metal tubing.

PFA Heat Shrink Tubing

PFA is offered as heat shrink tubing in addition to extruded tubing. PFA heat shrink products are just as resistant to chemicals and temperatures as regular PFA tubing. This tubing creates a tight, protective covering over components by shrinking to a predetermined size when heat is applied. PFA heat shrink can be used to create a smooth, non-stick surface on rollers or mandrels, protect sensors and probes from corrosive environments, and electrically insulate wires and connectors. Additionally, it serves as a barrier that is resistant to chemicals and moisture when components are encapsulated. PFA heat shrink is a flexible insulation and protection solution because of its capability to adapt to irregular shapes.

Comparing PFA with Other Fluoropolymers: FEP and PTFE

PFA is a member of the fluoropolymer family, which also includes the well-known substances FEP (fluorinated ethylene propylene) and PTFE (polytetrafluoroethylene). They differ greatly, so each is suitable for a particular use, even though they share some characteristics, such as superior chemical resistance. Understanding the distinctions between PTFE and FEP PFA tubing can help you make an informed choice when selecting materials. For applications requiring high flexibility and chemical resistance, flexible PTFE tubing is an excellent choice, especially in demanding industrial and medical environments.

Here’s a comparison of some key properties:

| Property | PFA (Perfluoroalkoxy) | FEP (Fluorinated Ethylene Propylene) | PTFE (Polytetrafluoroethylene) |

| Max. Continuous Service Temperature | ~260°C (500°F) | ~200°C (392°F) | ~260°C (500°F) |

| Clarity | Good to Excellent (depends on grade) | Excellent | Translucent to Opaque (typically milky white) |

| Flexibility | Good, better than PTFE at higher temps | Very Good, more flexible than PFA | Moderate, prone to creep |

| Permeability | Lower than FEP and PTFE for some gases/vapors | Higher than PFA | Higher than PFA, especially for certain gases |

| Melt Processable | Yes (injection molding, extrusion) | Yes (injection molding, extrusion) | No (processed by paste extrusion, sintering) |

| Tensile Strength | Higher than PTFE, similar to FEP | Good | Lower than PFA and FEP |

| Cost | Higher | Moderate | Lower to Moderate |

PFA often provides the best mix of melt processability (like FEP) and high-temperature performance (like PTFE). Additionally, it often has stronger creep resistance than PTFE tubing and better mechanical qualities at higher temperatures than FEP. Choosing between PFA, FEP, and PTFE frequently boils down to the application’s particular needs in terms of temperature, clarity, flexibility, permeability, and budget.

Choosing the Right PFA Tubing for Your Needs

Even though PFA tubing has several benefits, choosing the right kind isn’t always straightforward. To match the tubing to the particular requirements of your application, a number of variables need to be taken into account. These decisions may have an impact on your system’s longevity and general performance.

Consider Tubing Dimensions: Diameter and Wall Thickness

PFA tubing comes in a variety of diameters, ranging from larger diameter pipes for industrial processes to extremely tiny capillary tubes for analytical instruments. While the outer diameter (OD) is crucial for compatibility with fittings, tubing, and control products, the internal diameter (ID) will determine the flow rate capacity. Achieving ideal flow characteristics without putting undue strain on the tube or producing an excessive pressure drop is made possible by choosing the right size.

The PFA tubing’s kink resistance, flexibility, and pressure rating are all influenced by its wall thickness. Although they will be less flexible, thicker walls are typically more sturdy and have a higher pressure resistance. Thinner walls, on the other hand, provide more flexibility, which is advantageous for routing in confined areas, but they might not be appropriate for high-pressure applications. These characteristics may also be impacted by the resin grades selected.

PFA Resin Grades and Quality

PFA resin comes in a variety of grades, each with slightly different properties and formulations. Some grades aim for ultra-high purity with few extractables, longer flex life, increased clarity, or higher temperature resistance. Consulting a thorough product catalog or speaking with an informed supplier can help you find the best grade for your particular operating needs and regulatory requirements, such as FDA compliance for food contact. The purity of the PFA resin and the manufacturing process are also important considerations. High-quality tubes have smooth surfaces, uniform dimensions, and no defects. Credible producers provide documentation and regularly distribute case studies demonstrating the effectiveness of their products across a range of industries.

Fitting and System Component Compatibility

The type of fittings used with PFA tubing determines a long-lasting and leak-tight connection. Depending on the circumstances, it is essential to use fittings designed specifically for fluoropolymer tubing, such as PFA, or other materials that complement it, such as certain kinds of stainless steel. Hose fittings and conventional fittings used improperly can cause contamination, leaks, or even system failure. Consider the connection type, pressure rating, and chemical compatibility of the fittings. The options include compression fittings, flare fittings, and barbed fittings, each of which is suitable for a specific set of conditions. It is important that the entire fluid path, including all fittings, tubing, and control products, is compatible with the process fluids and operating conditions are essential.

PFA Tubing Installation and Maintenance

Regular maintenance and correct installation are crucial for extending the service life and performance of PFA tubing. By adhering to best practices, early failures can be prevented and system integrity maintained. This improves the user’s ability to use the equipment. If you need superior purity and thermal stability, PFA tubing offers outstanding performance in semiconductor and pharmaceutical applications.

Techniques for Proper Handling and Installation

Use fittings designed specifically for PFA tubing, which are typically made of PFA or another fluoropolymer that complements it. Determine if the fittings are tightened correctly in compliance with manufacturer specifications to prevent leaks without placing undue strain on the tubing. Always use a suitable, sharp cutter to cut tubing squarely so it has a good seal.

Despite PFA tubing’s degree of flexibility, avoid bending it past the recommended minimum bend radius. Sharp bends can create stress points that can eventually lead to kinking, flow restriction, or stress cracking and failure. Use the appropriate clamps and supports when routing tubing pfa lines to keep the tubing in place and prevent excessive movement or vibration. Soft curves will be possible as a result.

Preventative Maintenance and Routine Inspection

Despite PFA tubing’s exceptional durability, it’s wise to check it from time to time, especially in harsh environments or critical applications. Watch for signs of wear, kinking, cracking, discoloration, or elasticity changes. Early identification of potential issues helps prevent costly downtime and unexpected system failures.

Create an inspection schedule that considers the service’s severity and operational history. Maintain a record of every maintenance and inspection. Consider additional safety measures, such as double containment, for systems that handle hazardous materials when appropriate.

Cleaning and Sterilization Procedures

PFA tubing offers a number of advantages, including ease of cleaning, due to its low moisture absorption and non-stick surface. Residues can often be removed with a simple flush with purified water, a suitable solvent, or a detergent. The chosen cleaning agent should be compatible with PFA and any other system components.

For applications that require sterilization, such as those in the food processing or pharmaceutical industries, PFA tubing can withstand standard sterilization methods like autoclaving (steam sterilization), ethylene oxide (EtO) gas, or chemical sterilization. Always make sure the specific PFA grade and the entire assembly are compatible with the sterilizing method and settings of your choice.

Internet Resources and Additional Data

Reputable providers provide a multitude of online resources for choosing PFA tubing or looking for more specific information. Many offer a comprehensive online product catalog that is frequently categorized by a number of parameters. Typically, these catalogs provide specifications for various resin sizes, grades, and pressure ratings. Businesses may also release case studies that highlight effective implementations in a range of industries and provide instructional videos on how to install or maintain their products. Look for a FAQ area on their website to find answers to often asked topics. Examining a company’s privacy and cookie policies is also a good idea, particularly if you are giving them personally identifiable information.

The Future of PFA Tubing

High-performance materials like PFA tubing will become more and more necessary as industries develop and seek materials that can endure harsher environments. Exciting developments in this industry are being brought about by ongoing research and development, which is expanding the potential of PFA.

Development of Enhanced PFA Grades

New PFA resin grades with more outstanding properties are constantly being developed by manufacturers. This includes attempts to produce grades that are more resistant to certain aggressive chemicals, have higher maximum working temperatures, better mechanical strength (higher tensile strength), increased clarity, or even have lower permeability. The goal of these specialist classes is to satisfy the changing demands of high-tech sectors.

Innovations in Composite Materials

PFA composites, which mix PFA with other elements like reinforcing fibers or conductive additives, are gaining popularity. These composites might provide customized qualities, including reinforced tubing with noticeably higher pressure ratings or dimensional stability for applications involving extremely high temperatures, or static dissipative PFA tubing for handling volatile liquids.

Focus on Sustainable Manufacturing and Recycling

Sustainability is becoming more and more of a factor in materials science. The goal is to reduce manufacturing waste and energy consumption in order to produce PFA in a more environmentally friendly way. Although recycling fluoropolymers like PFA can be challenging, research into workable recycling strategies for spent PFA tubing and components is still underway with the aim of creating a more circular economy for these valuable materials.

Development of New and Emerging Uses

Because of its unique set of properties, PFA tubing can be used in cutting-edge technological fields. These include sophisticated cooling systems for electronics and data center infrastructure, advanced energy systems, state-of-the-art medical equipment, and specialized components for space exploration. As technology advances, PFA is likely to find new applications where its exceptional performance is crucial.

PFA tubing is now commonly acknowledged as a necessary component in many different industries. Its blend of high purity, mechanical durability, stability over a wide temperature range, and strong chemical resistance makes it an excellent choice for very demanding applications. PFA tubing consistently demonstrates its value and reliability in a range of environments, such as the highly hygienic semiconductor manufacturing facilities, the precise pharmaceutical industry, and the hygienic food processing industry.

As technology develops and industrial processes become more intricate, PFA tubing’s role is expected to continue expanding. PFA tubing provides a reliable solution whether you are designing a new chemical facility, modernizing analytical equipment, or creating cutting-edge medical devices. It is a material that facilitates advancement and improves safety and efficiency in crucial operations; it is more than just a conduit for fluids. Always remember to speak with a trustworthy supplier for specific needs. Contact Tef Cap Industries today for advice on PFA tubing information and application.