Install Teflon FEP Roll Covers

Preperation

Surface of roller must be smooth, clean and dry. Burrs, nick and adhesive residue must be removed prior to any install. Clean all oil, grease and petrochemicals from roller surface with non-petroleum solvents such as alcohol, chloroethene or acetone. Blow off all dirt, lint and debris.

Note : Metal rollers should be preheated to 120°F and then wiped clean removing all machining oils.

Note : Rollers manufactured of 100 % silicone cannot be bonded unless they are properly primed.

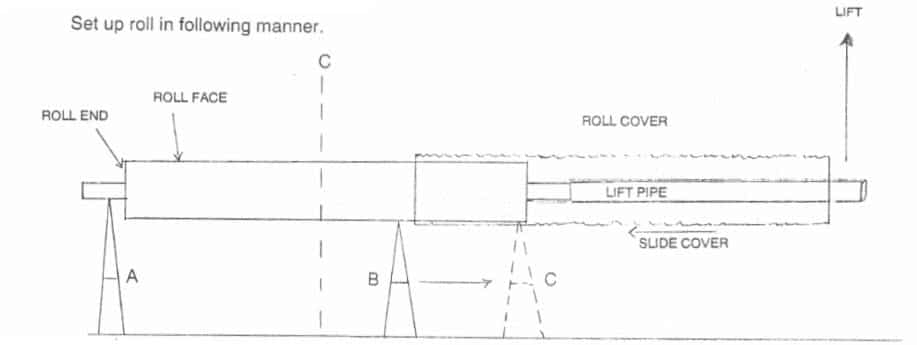

Set up and Slipping On Cover

Lift pipe should fit journal shaft fairly snuggly and be approximately 3/4 the length of the roll. The lift pipe should be kept clean with plastic or paper. Slide the cover over the lift pipe and up onto the roll. Lift the pipe and remove stand “B”. Slide the cover all the way onto the roll. Set the roll down onto a well-padded “C” stand and remove the pipe. Heavy metal rollers with small journal shafts will require special rigging.

Pre Shrink Prelimimaries

After setting roll (with the cover) in a lathe or on roller stands, take an open paper towel and wipe over the roll face to FEEL for contaminations under the roller cover or if there are any gel spots that could interfere with roller operations. If anything is detected, try blowing air under the cover to remove partials. Repeat process until ALL contaminations are gone. Obtain a heat gun capable of the producing temperatures of 500°F to 750°F.

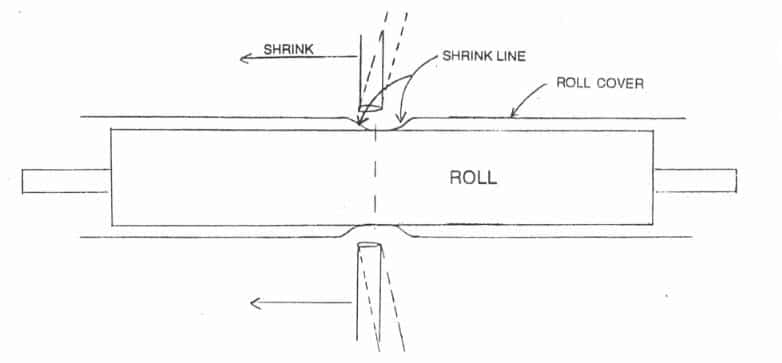

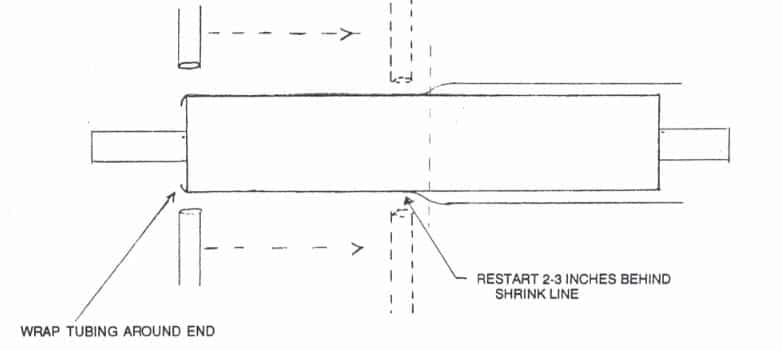

Shrinking Non Bonded Rollers

Center FEP Cover over the roller. Equal amount of overhang on each side. Start in the center using following guidelines.

Rollers from 4″ to 6″ Diameter : 2 Heat guns required

Rollers from 6″ to 10″ Diameter : 3 Heat guns required

Rollers from 10″ to 20″ Diameter : 4 Heat guns required

Rollers from 20″ & up : 6 Heat guns Required

If WRINKLES develop stop shrinking along with forward movement and try to push wrinkle or air bubble forward with a small rubber squeegee. If bubbles are hard to remove try cinching the roller with a cotton rope and work the bubbles towards the ends of the roller.