FEP (fluorinated ethylene propylene) was developed as a happy accident. Originally, the research that created FEP was focused on creating a cheaper way to produce PTFE (polytetrafluoroethylene), which had become the gold standard for its versatility. It’s known as the original fluoropolymer tubing and is still used today. However, FEP differs in key ways. An FEP tubing supplier could help you put FEP to work for your next project, and you may even be able to save money by using a superior material. Pay careful attention to the advantages of FEP, and you might identify a few telltale signs that your next project could benefit from FEP tubing.

Alternative

Many companies simply treat FEP as an alternative replacement for PTFE. This is perfectly understandable since they do share a number of similarities. As a bonus, FEP is cheaper than PTFE, as well. This is great for larger projects since the savings tend to scale better with the amount of tubing required.

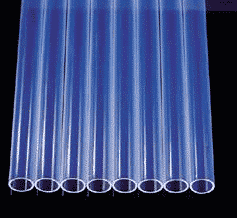

If you haven’t yet tried FEP as an alternative to PTFE, it’s certainly worth considering. The manufacturing innovations that helped to produce FEP in the first place also make it a great choice when you need longer lengths of tubing. FEP is a melt-processible fluoropolymer. This enables it to be manufactured in long, continuous lengths, unlike its predecessor PTFE.

Electrical

Almost every big project requires some sort of electrical work to go along with it. FEP tubing is ideal for any work that demands cabling and electrical insulation. This certainly includes any job that demands foamed coaxial cables, foamed plenum wires, or coating for telephone wires. New construction, renovations, or infrastructure development are all viable candidates. One major advantage is that FEP doesn’t generate as much heat when insulting electrical components. As you know, heat is the bane of modern technology. It can prematurely age systems and contribute to damage over time or every outright failure. If higher temperatures are expected, FEP can maintain performance at higher temperatures, as much as 450 degrees Fahrenheit.

Organization

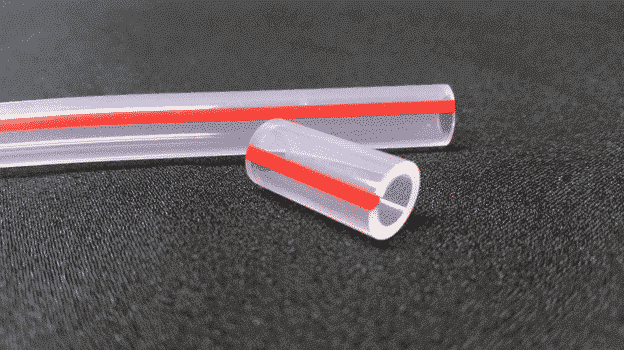

Sometimes, it’s not enough to simply have ample amounts of cost-effective tubing. You need to keep it organized and arranged carefully. FEP tubing can be manufactured as clear tubing, or it can be produced in a wide variety of colors. Every electrician and network specialist appreciates how helpful this is. During work, this allows the tubing to be easily identified, categorized, labeled, and organized. This is a great way to save time and frustration. Data centers sometimes have incredibly intricate and complicated arrangements. Color-coordinated or labeled cabling makes it much easier to tackle this sort of complex work.

Pressure

Harsh environments limit the sort of materials that are viable. They have to be able to handle temperature extremes, and in some cases, extreme pressure as well. When compared to PTFE, FEP tubing is able to maintain working conditions at 30% higher pressure than PFTE. Although this won’t be applicable to every project, it’s absolutely essential in some instances. For certain medical devices or automotive applications, FEP is clearly superior to its forerunner.

Obviously, PTFE isn’t completely obsolete. It’s widely used and continues to perform well. However, when compared to modern FEP tubing, it’s more expensive and outclassed in key areas. If you want to save money or provide higher-quality tubing, it’s the obvious choice. Speak with Tef-Cap Industries at 610-692-2576 and learn how an FEP tubing supplier can help your next project be a huge success.