Polytetrafluoroethylene tubing, or PTFE, has been around since the 1960s, and in that time, it has come to be a commonly used option in a wide variety of tubing applications. It’s excellent insulative properties make it ideal for use in applications where electricity is involved. The flexibility and durability of PTFE tubing make it a popular choice in the aerospace and automotive industries, where it’s durable and resilient under rigorous use. Its sterile and inert qualities make it a wise choice of those in the medical, pharmaceutical, and food and beverage industries.

The beneficial features of tubing produced by a high-quality PTFE tubing manufacturer are many, which is why its uses span the modern industrial, medical, and manufacturing landscape. While many understand a few key features of this tubing type, there are many lesser-known advantages to PTFE tubing that are important to note. Keep reading to learn more.

Water Resistant

Water Resistant

Like many fluoropolymers, PTFE is a hydrophobic substance. That means instead of absorbing water, it repels it. That not only means that it’s largely impermeable, but it also won’t leach its components into materials that are contained in the tubing, since it’s not soluble when in the presence of water.

Chemical Resistant

One of the greatest strengths of PTFE tubing is that it’s insoluble not only in the presence of water, the universal solvent, but when exposed to many more caustic and corrosive liquids as well. It’s highly resistant to a variety of chemicals such as alcohols, acids, solvents, esters, and biological fluids and won’t break down in their presence. Despite its incredible ability to tolerate chemicals, there are a few compounds such as chlorine trifluoride, molten alkalis, and gaseous fluorine that can cause PTFE to degrade and break down.

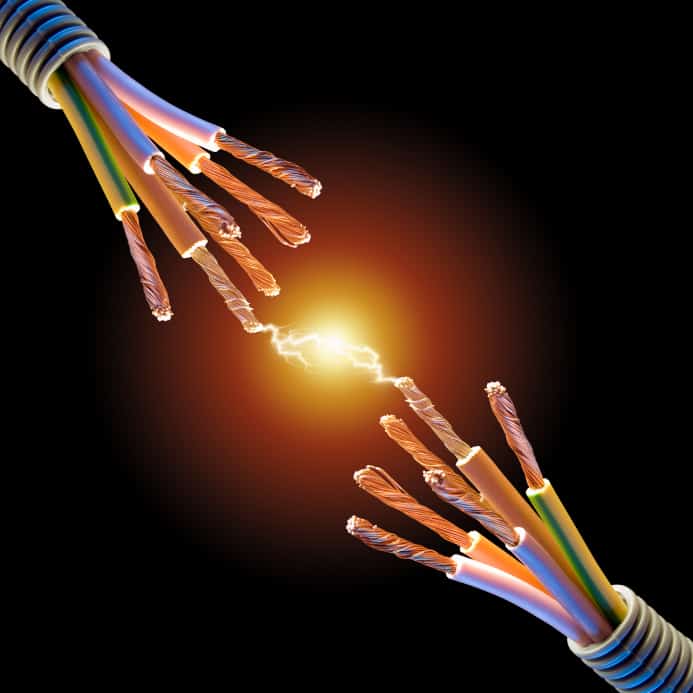

Electrical Properties

PTFE is widespread in electrical applications because of its multitude of beneficial electrical properties. It has a great dielectric constant and a high electrical breakdown voltage rating. It also has a beneficial surface resistivity level. That makes it perfect for use in insulating wires and electrical components.

Impressive Thermal Qualities

Many plastics are highly susceptible to the influence of temperatures and their beneficial properties may degrade if the temperature fluctuates. PTFE isn’t among those substances, however, as it can retain its advantageous qualities regardless of the temperature better than many other fluoropolymers. It can tolerate temperatures from -200 degrees C to 260 degrees C without any change in flexibility, stability, or electrical resistance.

Low Coefficient of Friction

Low Coefficient of Friction

Coefficient of friction is a value that describes the ease with which a material allows liquid and substances to slide past its surfaces. In other words, the more favorable the coefficient of friction of a material, the more easily fluids and substances flow over or through it. PTFE has an extremely low coefficient of friction, which means that any liquid or substance traveling over or through a PTFE surface will flow smoothly and consistently. Not only is that important in applications where a consistent rate of flow is necessary, but it can also prevent the formation of deposits over long periods that can lead to blockage or sources of contamination. Low coefficient of friction is also beneficial in electrical applications, such as in the automotive or aerospace industries where vibration leads to tubing abrasion. Such abrasion can lead to damaged wire insulation or compromised tubing, and in the automotive and aerospace fields, such factors can negatively impact user safety.

There’s a good reason that PTFE tubing is found in many facets of modern life, as its benefits are many and its usage in industry is widespread. To learn more about the beneficial features of PTFE tubing, contact Tef-Cap Industries at (610) 692-2576.