Heat shrinkage tubing is the process of decreasing the size of plastic tubes that are used to insulate cables and wires. This will allow you to better insulate the wires or provide resistance to potential abrasion. While you may be interested in using heat shrinking tubing for your wire or cable insulation, you may also wonder how this process came about and how it works. Here is some more information on the history and process of heat shrinkable PTFE tubing.

Invention of Heat Shrink

The process of heat shrink tubing was pioneered in the 1950s by the Raychem Corporation and its founder, Paul Cook. A chemical engineer, Cook founded his company with a focus on radiation chemistry, which is how the name of the company came about. Cook invented two products that would be the primary focus of his company: lightweight aircraft cables and heat-shrinkable tubing. While the Raychem Corporation was the pioneer of this process, it has since become widely used by a variety of companies within the industry.

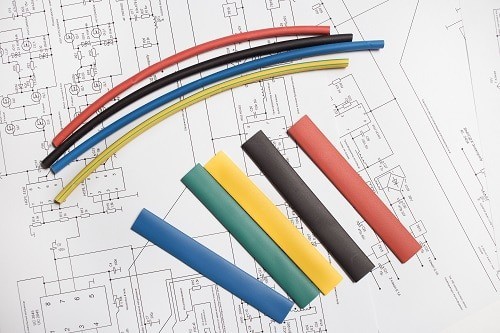

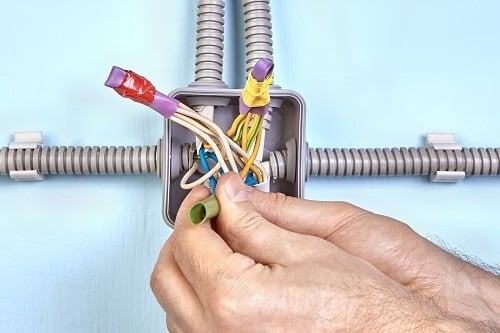

Uses of Heat Shrinkable Tubes

Heat shrinkable tubes are typically used for two purposes: protection, and the cosmetic changes of cables and wires. This process can protect cables and wires by sealing water or dust out and away from the cables, protecting the cable or wiring from extreme heat, and providing a barrier between cable or wires and any chemicals that could corrode them. From a cosmetic point of view, you can create a color code for identification purposes, gather wires together, or improve the appearance of the wires.

Making Heat Shrinking Tubes

There are a variety of thermoplastics that heat shrinking tubes can be made out of including polyolefin, polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE), and fluorinated ethylene propylene (FEP). If conductivity is an issue, a conductive polymer thick film can also be used to connect multiple conductive objects through tubing without the need to solder them. If the need arises, you may be able to add an adhesive lining that will make the tubing waterproof.

Why the Tubing is Shrinkable

Plastic tubing itself will not shrink when exposed to heat, so a process called cross-linking was created to complete the process. Cross-linking occurs when the plastic is exposed to a certain amount of radiation. After World War II, it was discovered that exposing plastics to radiation would allow you to intentionally alter the molecular structure without them melting. A process called covalent bonding between the atoms of the polymer allowed it to experience plastic memory. This means that when the plastic is cross-linked and expanded in shape, it will instinctively return to its original size when exposed to a specific amount of heat.

How Much Shrinkage?

You may want to heat shrink your tubing, but only a certain amount. So how do you know how much it will shrink? All heat shrinking tubing is provided with a shrink ratio that will tell you how much it can potentially shrink. The ratio is decided based on how small it will become compared to its original size. For example, if your heat shrink ratio is 5:1, the tubing is capable of shrinking up to one-fifth of its expanded size.

Heat shrink tubing allows you the ability to protect your cables and wires or make cosmetic changes. Once the primary product of an innovative company, heat shrinkable PTFE tubing has become an industry standard.