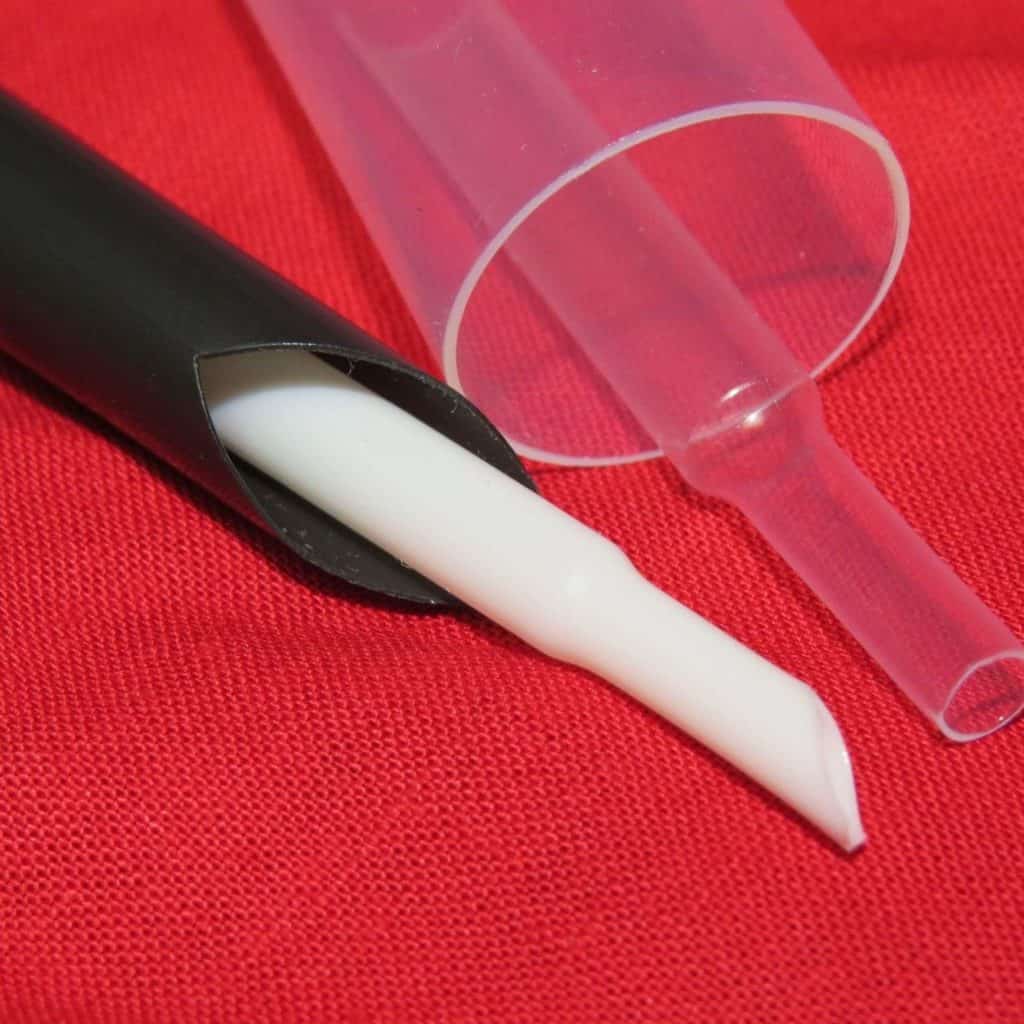

There are a number of demands which need to be met by any material that’s going to be utilized for the purpose of electrical wire insulation. Manufacturers and electricians need to rely on a material that’s tough but malleable. It needs to be able to melt so that it can be formed into a variety of different tube shapes to suit a number of purposes. It will need to be heat resistant and, of course, none of these properties are of any use it the material isn’t cost-effective. These days, one of the most common materials used for insulating wires in electrical systems and circuit boards is FEP (fluorinated ethylene propylene). Heat-shrink tubing of FEP for the purpose of insulation and as a jacket material has proven incredibly important in recent years to preserve the integrity and effectiveness of wiring in dozens of prominent industries. Here are a few of the reasons why.

A Meltable Material

FEP is a fluoropolymer that’s a variation of Teflon or PTFE. It shares many of the properties and applications of PTFE. It has a very low coefficient of friction, can operate effectively across a broad range of temperatures, and is chemical and heat resistant. Like PTFE, it’s nonstick, and when it comes to corrosion resistance, FEP is the only readily available fluoropolymer—besides PTFE—that can match its resistance to caustic agents. A principal difference with its Teflon counterpart is that FEP has a lower melting point and is therefore melt-processable. FEP can be manufactured via conventional injection molding and, thus, can easily form into different shapes and varying lengths.

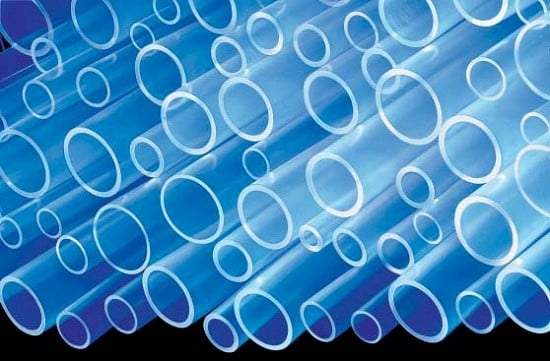

Highly Versatile

While most commonly extruded as an insulator, FEP can also provide jacket material for wire and cable. Highly malleable, it’s somewhat more flexible than PTFE and can even be foamed as a dielectric in coaxial cables. It’s for these reasons, as well as its ability to be manufactured in a variety of shapes and lengths, that FEP is frequently the material of choice in a broad range of industries such as aerospace, automobile, lighting, and medical.

Economic Benefits

If you’re in manufacturing or working in any industry that requires the production of great lengths of electrical cable—and therefore, insulation—even the smallest difference in price between one material and the next can mean the difference between success and failure. As the less expensive option for insulation compared to PTFE, FEP is highly sought after by manufacturers. Furthermore, it’s highly resistant to sunlight, so it’s unlikely to ever degrade or crack over time even in sunny, outdoor conditions. This further enhances the savings that are possible when using FEP as an insulator.

Heat-shrink FEP tubing has a variety of applications, but it’s uniquely suited to fill the role of perhaps the best wire insulator in the industry. If you want to take advantage of the durability, meltability, and heat and chemical resistance that only FEP tubing has to offer, contact Tef-Cap Industries, Inc., at (610) 692-2576 and we’ll help you with any questions you might have to satisfy all your electrical insulation needs. Give us a call today!