High-Quality PTFE, FEP, PFA Tubing & Products

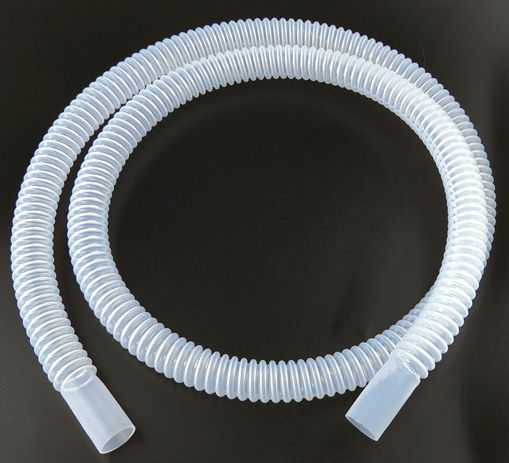

Serving the needs of high-demand industries such as aerospace, medical, chemical processing, electrical, and semiconductor, Tef-Cap Industries offers more than 50 years of experience with Fluoropolymer Tubing (Teflon) and has quickly become one of the leaders in chemical resistance and fluid handling. Custom fabrication of PTFE, FEP, and PFA fluoropolymer tubing, along with quick turnaround, puts Tef-Cap in a position to respond to the needs of the ever-changing environment and fields where precision and quality count. Tef-Cap Industries manufactures and stocks a complete line of heat-shrinkable PTFE, FEP, and PFA tubing, all from FDA and USP Class VI approved resins. We offer large-diameter heat-shrinkable FEP roll covers; extruded smoothbore FEP, PFA, and PTFE spaghetti tubing in American Wire Gauge (AWG) sizes; convoluted PTFE tubing in both standard flex and extra flex; corrugated FEP tubing; and Teflon PTFE tubing.

We specialize in the design of heat-shrinkable FEP and heat-shrinkable PFA probe covers for sensors, thermocouples, probes, thermometers, and RTD’s that help ensure the life of delicate instruments and measuring devices in corrosive environments.

Heat Shrink Tubing

Flexible Tubing

High Quality Industrial Tubing Solutions

Established in 1986 Tef Cap Industries has become one of the leading manufacturers of Heat Shrinkable PTFE, FEP, PFA Tubing and Fluoropolymer Products for the aero-space, automotive, chemical, pharmaceutical, medical, food, semiconductor and electronics industries. Since its inception Tef Cap’s Fluoropolymer Tubing line has grown to include resins such as PTFE, PFA, FEP, MFA, THV, ETFE, ECTFE, PVDF, and PEEK , all of which are designed for a wide range of high purity and corrosive applications and able to withstand temperature ranges from -275°F to 500°F.

Specializing in Heat Shrinkable Sleeves, Tef Cap Industries produces commercial heat shrinkable fluoropolymers that meet the dimensional requirements of both 23053/11 and 23053/12 specifications. Tef Cap can also produce custom sizes and shrink ratios in Teflon PTFE Tubing, Teflon FEP Tubing and Teflon PFA Tubing. Our secondary processes on Fluoropolymer Tubing include Sealing, Cuffing, Flaring, Cutting, Slitting, Etching, Thermosetting and Striping. Tef Cap also installs FEP Roll Covers and Encapsulates Thermocouples, Probes and Thermometers with a shrinkable FEP or PFA Probe Cover all in house saving customers both time and money.

From Wall Thickness to Color, We Produce Tubing to Fit any Specification

Tef Cap Industries, a trusted PFA tubing manufacturer, makes a wide range of tubing solutions for a wide spectrum of industries, from medical and aerospace to industrial and more. Our fluoropolymer tubing can be produced to fit any specification, from thickness to color, and more to meet your needs. Our durable, reliable tubing ensures you receive products that provide exceptional performance, durability, and reliability. If your business needs high-quality custom fluoropolymer tubing, you can depend on us to deliver.

What are the Benefits of Fluoropolymer Tubing?

- Extreme Chemical Resistance: Fluoropolymer tubing is highly resistant to a wide range of solvents and chemicals to prevent any degradation or reaction to fluids or other materials that go through it without causing it to shrink or disintegrate/dissolve.

- High-Temperature Resistance: This material has an impressive temperature resistance that can withstand extreme heat or cold, from -200 to 260 degrees Celsius, or -328 to 500 degrees Fahrenheit, for unparalleled versatility across many applications, even at a high temperature.

- Low Coefficient of Friction: Get less tube drag with fluoropolymer tubing thanks to its chemical composition, which creates an extremely slippery, nonstick surface that allows for smooth, even movement of liquids and other materials within the tubing. It demonstrates extremely minimal resistance to friction, making it a good option for various industries and applications.

- Non-Stick Properties: Thanks to its nonstick properties, this tubing doesn’t easily adhere to other materials or surfaces, even when exposed to a high temperature.

- Excellent Electrical Insulation: Fluoropolymer tubing is an outstanding electrical insulator thanks to a low dielectric constant that makes it ideal for insulating wires and cables at high voltages. This tubing works well for high-voltage transmission cables, splicing in corrosive environments, fiber optics, and protecting electronic leads.

- Weather Resistance: Not only is it resistant to heat, cold, and corrosion, but fluoropolymer tubing maintains its integrity and will not shrink or warp under a range of weather conditions, including UV rays (sunlight), rain, and waste gases, making it a great choice for aerospace, automotive, and electronics applications, even when used in an outdoor environment.