Thin Wall PTFE Tubing: Different Applications Explained

The demand for PTFE tubing is growing, mainly because it is so versatile that it can be used in almost every industry imaginable. From medical devices to electrical wiring tubing to piping, the list of applications for thick and thin wall PTFE tubing is impressive and...

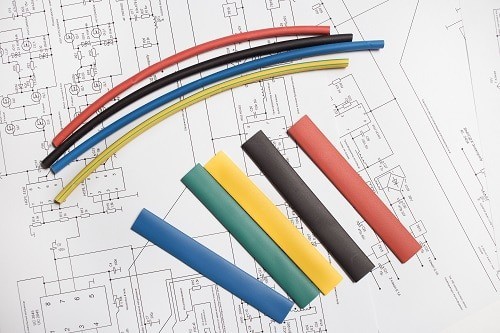

4 Unique Uses for Heat Shrink Tubing

PTFE tubing is used to solve a wide variety of industrial repair problems, but you can also use it in your home or office to fix everyday problems like frayed wires and worn shoelaces. Keep reading to learn more. Frayed and Frazzled In the era of cellular technology,...

Reasons Why Medical Device Manufacturers Should Choose PTFE Tubing

One constant in the highly competitive medical device manufacturing industry is the quest to produce improved devices with better and better performance ratios. This challenge has created several sub-challenges, one of which was to figure out how to join metal and...

PTFE Heat Shrinkage Tubing: Where It Began

Heat shrinkage tubing is the process of decreasing the size of plastic tubes that are used to insulate cables and wires. This will allow you to better insulate the wires or provide resistance to potential abrasion. While you may be interested in using heat shrinking...

PTFE Tubing and Hoses Manufactured for Aerospace and Aviation

Installation of PTFE tube has become an indispensable activity for every organization to conduct operating activities smoothly and protect the web of wires from any kind of accident. Often, known as polytetrafluoroethylene, in the beginning the PTFE was used only in...