AWG Heat Shrink FEP 1.3:1 • 23053/11

FEP 1.3:1 Heat Shrink Tubing (Fluorinated Ethylene Propylene) is a high-temperature, chemical-resistant fluoropolymer designed for applications requiring lower shrink temperatures than PTFE, while offering enhanced flexibility, superior optical clarity, and excellent non-stick (release) properties.

Available in both AWG (American Wire Gauge) and fractional sizes, FEP heat shrink tubing serves as a popular alternative to PTFE-based tubing, which typically requires a much higher shrink activation temperature of around 624°F. In contrast, FEP heat shrink tubing begins shrinking at significantly lower temperatures, making it easier to work with across various applications.

Capable of withstanding extreme conditions—from cryogenic environments up to 400°F—FEP heat shrink tubing maintains its integrity without compromising safety. Additionally, it is FDA-compliant for food contact, making it suitable for medical, pharmaceutical, and food processing applications where purity and performance are critical.

Tef Cap can manufacture Heat Shrink FEP Tubes for custom applications and also produces heat shrink tubing that is Biocompatible and USP Class VI compliant. FEP Heat Shrink Tubing can be produced in standard 4 ft lengths or on spools with long continuous lengths for automated cutting machines. These long spools help eliminate waste and speed up assembly.

Heat Shrink FEP Tubing / Heat Shrink FEP Tube with a 1.3:1 will cover a large range of product sizes but is limited in its shrink ratio. For odd shapes and lengths Tef Cap can also manufacture a custom FEP Heat Shrink Tube designed specifically for your needs. For a larger shrink ratio please see FEP 1.6:1 Heat Shrink Tubing.

Features of FEP Heat Shrink Tubing

- Easier to shrink than PTFE

- Max Temperature Range 400°F

- Flame Rating : UL 94 VO

- Chemically inert

- Lower gas and vapor permeability than PTFE

- Excellent UV transmission

- Self extinguishing

- Fractional & AWG Sizes

- Dimensionally Compliant to 23053/11

- Equal to FIT-400

FEP 1.3:1 Heat Shrink Tubing AWG

| AWG Size | Expanded ID | Recovered ID | Wall Thickness | AMS-DTL-23053/11 |

|---|---|---|---|---|

| AWG 24 | .031 | .027 | .008 +/- .002 | 23053/11-101 |

| AWG 22 | .036 | .032 | .008 +/- .002 | 23053/11-102 |

| AWG 20 | .045 | .039 | .008 +/- .002 | 23053/11-103 |

| AWG 18 | .060 | .049 | .008 +/- .002 | 23053/11-104 |

| AWG 16 | .075 | .061 | .009 +/- .002 | 23053/11-105 |

| AWG 14 | .092 | .072 | .009 +/- .002 | 23053/11-106 |

| AWG 12 | .115 | .089 | .009 +/- .002 | 23053/11-107 |

| AWG 10 | .141 | .114 | .010 +/- .003 | 23053/11-108 |

| AWG 9 | .158 | .124 | .010 +/- .003 | 23053/11-109 |

| AWG 8 | .180 | .143 | .010 +/- .003 | 23053/11-110 |

| AWG 7 | .197 | .158 | .011 +/- .004 | 23053/11-111 |

| AWG 6 | .225 | .180 | .011 +/- .004 | 23053/11-112 |

| AWG 5 | .248 | .198 | .011 +/- .004 | 23053/11-113 |

| AWG 4 | .290 | .226 | .011 +/- .004 | 23053/11-114 |

| AWG 3 | .310 | .249 | .011 +/- .004 | 23053/11-115 |

| AWG 2 | .365 | .280 | .012 +/- .004 | 23053/11-116 |

| AWG 1 | .400 | .311 | .012 +/- .004 | 23053/11-117 |

| AWG 0 | .440 | .349 | .012 +/- .004 | 23053/11-118 |

FEP 1.3:1 Heat Shrink Tubing Fractional

| Size | Expanded ID | Recovered ID | Wall | AMS-DTL-23053/11 |

|---|---|---|---|---|

| 3/8 | .500 | .383 | .015 +/- .004 | 23053/11-119 |

| 7/16 | .580 | .448 | .020 +/- .004 | 23053/11-120 |

| 1/2 | .666 | .510 | .020 +/-.004 | 23053/11-121 |

| 5/8 | .830 | .637 | .025 +/- .004 | 23053/11-122 |

| 3/4 | 1.000 | .764 | .030 +/- .004 | 23053/11-123 |

| 7/8 | 1.170 | .891 | .035 +/- .004 | 23053/11-124 |

| 1 | 1.330 | 1.020 | .035 +/- .004 | 23053/11-126 |

| 1 1/8 | 1.500 | 1.145 | .035 +/- .004 | 23053/11-133 |

| 1 1/4 | 1.666 | 1.270 | .035 +/- .004 | 23053/11-134 |

| 1 3/8 | 1.833 | 1.390 | .035 +/- .004 | 23053/11-135 |

| 1 1/2 | 2.000 | 1.570 | .035 +/- .004 | 23053/11-136 |

* Mil Spec #’s are for size and cross ref only.

* Mil Spec 23053/11 material available upon special quote.

FEP 1.3:1 Heat Shrink Tubing

- AMS-DTL-23053/11 (Dimensional Reference Only)

- Dielectric Strength: > 2,000 V/M

- Shrink Temperature: 230°F

- Temperature Range: -100 to 400°F

- Standard Lengths: 4 ft and coils

- Color : Translucent ( Colored FEP available upon request )

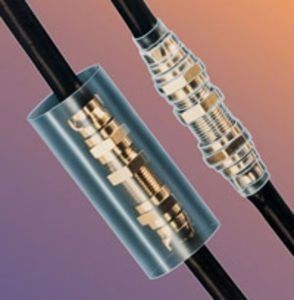

Reliable Sealed Protection With FEP 1.3:1 Heat Shrinkable Tubing

Tef Cap provides the finest quality 1.3:1 Heat Shrink FEP Tubes. Our products are designed to provide items utmost protection against excess amount of environmental heat. Highly flexible and expandable, these shrink tubes, when subjected to heat, can mold into irregular shapes, providing reliable sealed protection to enclosed items.

Shrinking Instructions

For long wires and tubes start at one end and evenly heat the surface making sure to rotate the part or the heat source so that recovery does not come completely off of one side. Rotating will give you a uniform shrink eliminating air bubbles and keeping the wall even throughout the part. If parts cannot be rotated most heat guns come with a shield or a deflector that can be used in place of rotating. Large metal parts would fare better if they can be pre heated to take the chill off of the part and warm the surface. Over heating the part will cause shrinking to occur prematurely throughout the tube and anywhere the tubing might have come into contact with the hot surface.

Over heating Heat Shrink FEP Tubes while shrinking will cause it to crack and become brittle. If this happens the FEP will have a cloudy appearance in spots. Please keep in mind that FEP tubing will ACTUALLY sometimes grow in length during shrinking and that material will bunch and wrinkle if it is not allowed to slide and grow over the part.

FEP 1.3:1 Heat Shrink Tubing • 23053/11

23053/11-101, 23053/11-102, 23053/11-103, 23053/11-104, 23053/11-105, 23053/11-106, 23053/11-107, 23053/11-108, 23053/11-109, 23053/11-110, 23053/11-111, 23053/11-11213, 23053/11-114, 23053/11-115, 23053/11-116, 23053/11-117, 23053/11-118, 23053/11-119, 23053/11-120, 23053/11-121, 23053/11-122, 23053/11-123, 23053/11-124, 23053/11-126, 23053/11-127

AWG Heat Shrink FEP 1.3 Sizing

AWG # 24 Heat Shrink FEP ( FIT-400-24 ), AWG # 22 Heat Shrink FEP ( FIT-400-22 ) , AWG # 20 Heat Shrink FEP ( FIT-400-20 ) , AWG # 18 Heat Shrink FEP ( FIT-400-18 ) , AWG # 16 Heat Shrink FEP ( FIT-400-16 ) , AWG # 14 Heat Shrink FEP ( FIT-400-14 ) , AWG # 12 Heat Shrink FEP ( FIT-400-12 ) , AWG # 10 Heat Shrink FEP ( FIT-400-10 ) , AWG # 9 Heat Shrink FEP ( FIT-400-9 ) , AWG # 8 Heat Shrink FEP ( FIT-400-8 ) , AWG # 7 Heat Shrink FEP ( FIT-400-7 ) , AWG # 6 Heat Shrink FEP ( FIT-400-6 ) , AWG # 5 Heat Shrink FEP ( FIT-400-5 ) , AWG # 4 Heat Shrink FEP ( FIT-400-4 ) , AWG # 3 Heat Shrink FEP ( FIT-400-3 ) , AWG # 2 Heat Shrink FEP ( FIT-400-2 ) , AWG # 1 Heat Shrink FEP ( FIT-400-1 ) , AWG # 0 Heat Shrink FEP ( FIT-400-0 )

Fractional Heat Shrink FEP 1.3 Sizing

3/8 Heat Shrink FEP 1.3 , 7/16 Heat Shrink FEP 1.3 , 1/2 Heat Shrink FEP 1.3 , 5/8 Heat Shrink FEP 1.3 , 3/4 Heat Shrink FEP 1.3 , 7/8 Heat Shrink FEP 1.3 , 1 Heat Shrink FEP 1.3 , 1 1/8 Heat Shrink FEP 1.3 , 1 1/4 Heat Shrink FEP 1.3 , 1 3/8 Heat Shrink FEP 1.3 , 1 1/2 Heat Shrink FEP 1.3

Recovery Temperature

| Specification | FEP | PTFE | Dual Wall PTFE/FEP | PEEK |

|---|---|---|---|---|

| Expanded ID < 1.00" | 410°F +/- 10° | 662°F +/- 8° for 10 minutes | 625°F | 650°F |

| Expanded ID > 1.00" | 430°F +/- 10° | 662°F +/- 8° for 10 minutes | 625°F | 650°F |

| Mil Spec | 23053/11 | 23053/12 | N/A | N/A |

An Excellent Solution for Sensitive Electrical Components in Hazardous Conditions

Tef Cap Industries is one of the leading manufacturers of heat-shrink FEP tubing, Teflon FEP shrinkable roll covers, and more. We offer a wide selection of products for use in many industries, including electrical construction, medical, cable, and others. Explore our catalog today if you’re looking for durable heat shrink FEP tubing from a trusted manufacturer. Because we’re a custom manufacturer, you can also order customized materials to suit your exact specifications.

What Applications are Best for Shrinkable FEP Tubing?

Our shrinkable (heat shrink) FEP tubing can be utilized for many applications, including:

- Electrical Insulation and Protection: FEP tubing is excellent for electrical insulation and protection thanks to its excellent dielectric properties, chemical stability, and high-temperature resistance. It’s a good choice to cover and insulate wires, cables, and electrical connections, even in harsh environments where high heat or chemical exposure is a concern.

- Mechanical Protection: This tubing is ideal for protecting mechanical components and machinery like shafts, rollers, and sensors from abrasion, wear and tear from friction, and other types of physical damage, as it creates a tight and durable covering when heat is applied.

- Medical Applications: Heat shrink FEP tubing works well in medical applications like catheters, surgical instruments, and other medical devices to protect them from damage during insertion and movement while within the body.

- Chemical and Industrial Applications: FEP tubing works to transfer corrosive chemicals by adding an extra layer of insulation while preventing leaks. It can also seal leaks in pipes that transfer harsh chemicals to prevent rust, corrosion, and contamination.

- Food and Beverage Processing: This material is ideal for use in dairies where hygiene is vital, as well as for drink dispensing and food processing, thanks to its safe, nontoxic properties that help to prevent contamination or the spread of germs and bacteria.

- Aerospace and Automotive: FEP tubing is often used in both the aerospace and automotive manufacturing and production industries, from wire harnessing to fluid protection.

- Fluid Transfer Lines: This tubing provides a sterile fluid transfer, making it a good choice for a wide range of uses where safety and hygiene are paramount.